On-site NDT stiffness assessment and defect detection for composite materials

SINTEG Systems gives composite quality control and manufacturing teams instant insights in material defects and stiffness properties – without lab testing or part destruction

OUR PARTNERS

Why we exist

Traditional NDT methods for composite materials are slow, expensive, and limited in what they reveal

Composite materials are at the core of modern engineering, offering unmatched strength-to-weight ratios, durability, and design flexibilities. However, ensuring their structural integrity remains a challenge. Traditional non-destructive testing (NDT) methods are often slow, expensive, and limited in what they reveal, leading to low product reliability, excessive safety factors, and increased production costs.

At SINTEG Systems, we are redefining composite material inspection by offering a real-time, on-site integrity assessment technology to improve product efficiency while meeting strict regulatory demands. Our goal is to support safe, sustainable, and reliable use of composites across all existing and emerging industries.

Call for collaboration

We are currently in the validation phase, working with key industry players to refine our technology. We are actively looking for manufacturing partners and early adopters who want to shape the future of composite NDT with us.

our solution

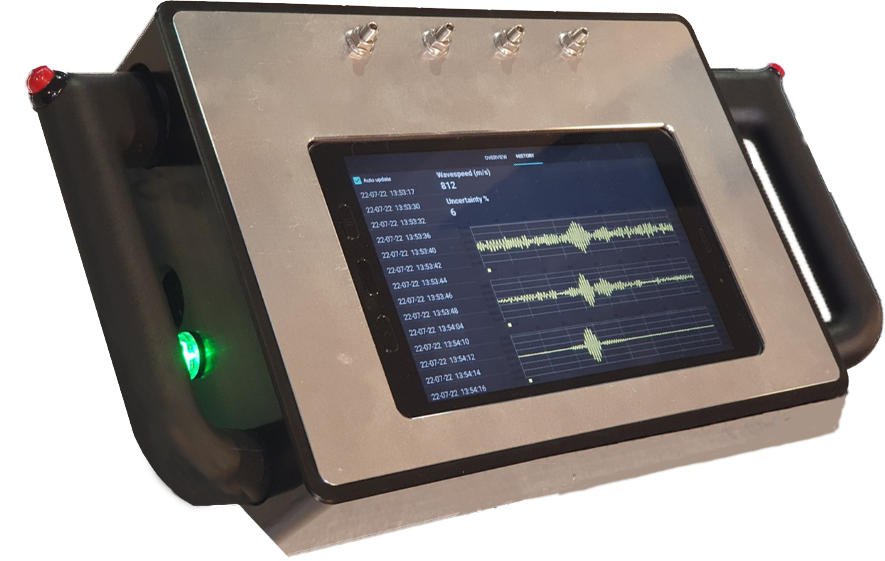

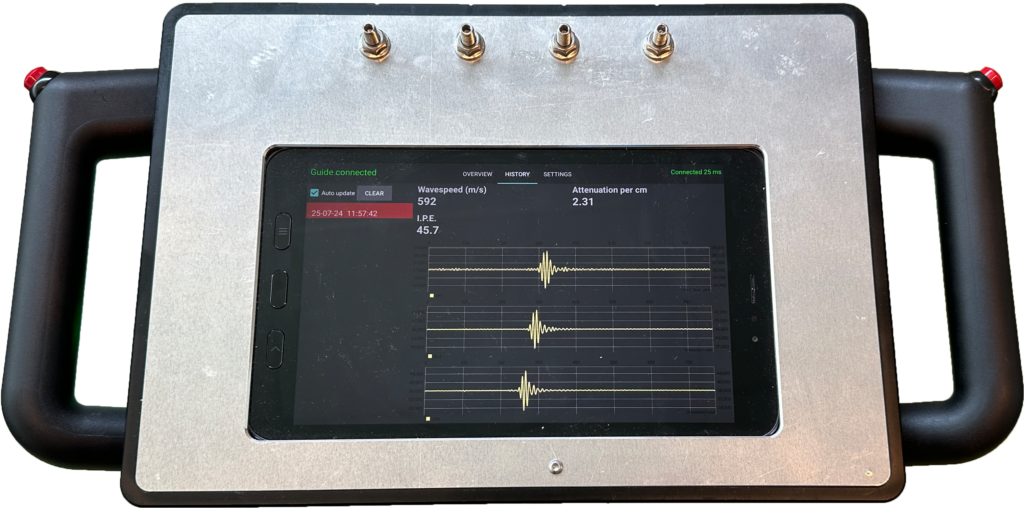

A compact ultrasonic NDT system that analyses both defects and material stiffness — on-site, in real time

We believe that composite NDT should be smarter, more efficient, and more accessible. With our innovative ultrasound-based inspection technology, manufacturers can move beyond simple pass/fail inspections. SINTEG provides a quantifiable assessment of material integrity, ensuring product reliability and extending component lifecycles.

Our solutions are designed to be cost-effective, scalable, and user-friendly, eliminating complex testing procedures through ML-driven stiffness analysis and automated defect localisation.

Quantitative stiffness analysis

Our innovative algorithm reveals undesired stiffness variations after manufacturing and monitors their development during lifetime

Rapid inspection

Large areas can be quickly assessed for quality control and in-service checks, reducing inspection time and increasing efficiency

Easy-to-use

No coupling agent is needed, simplifying the process of post-manufacturing quality control and in-service inspection

On-site inspection

A wireless, portable system that works in any location, from existing production lines to in-service inspections

ML-driven analysis

Automated data processing and result interpretation makes our system usable by any level of expertise while eliminating human errors

Compatible with all composites

Adaptable sensor design makes our system suitable for various composite materials and structures.

Key benefits of SINTEG Systems

Eliminate excessive safety factors

Our quantitative inspection method reveals undesired stiffness variations across the composite structure. The intuitive analysis supports improvements in structural design and production procedures, paving the way for reduced safety factors and structural weight

Minimize inspection costs

The efficient design of our system allows quality control and inspection procedures to be performed by any person, regardless of expertise, with minimal training. The portable, non-intrusive system seamlessly integrates into production lines for process control or dedicated inspection workflows — without causing delays or downtimes

Increase quality assurance

The ML-based data analysis and result interpretations eliminate the chance of human errors. The automated evaluation process ensures consistent, objective assessments, enhancing structural reliability while ensuring regulatory compliance.

Maximize structural lifetime

Detecting production-induced defects and stiffness variations, combined with monitoring structural integrity during service, ensures optimal performance and extends the structure’s lifetime.

our industries

Advanced in-situ structural integrity solutions for high-performance composite structures

Aerospace

In aerospace composites, stiffness loss and hidden bondline defects are difficult to validate and even harder to monitor once structures move beyond the lab. Conventional inspection methods are local, access dependent, and poorly suited to large or integrated composite parts.

SINTEG Systems enables large area guided wave inspections that quantify structural stiffness and reveal integrity issues in laminates and bonded joints without full surface access. This allows R&D teams to validate models and designs, production teams to strengthen QA and QC, and MRO engineers to assess in service structural performance based on measurable data rather than assumptions.

Renewables

Large composite structures such as wind turbine blades, hydrogen storage tanks, and composite pipelines are typically qualified through long duration fatigue and load testing, where stiffness degradation only becomes visible late in the test or at failure. This makes test campaigns time consuming, expensive, and poorly suited to early design iteration.

By tracking stiffness changes and structural behaviour during testing, guided wave measurements can provide insight well before visible damage or failure occurs. This allows manufacturers to shorten fatigue test cycles, identify weak designs earlier, and reduce reliance on full scale destructive testing while maintaining confidence in structural performance.

Naval and subsea

Composite and hybrid structures in naval vessels are subject to fatigue, impact, and long service lives, while inspection opportunities are limited. Conventional NDT methods provide local information but struggle to capture global structural behaviour.

Our technology allows for the detection of material stiffness and integrity changes across large structural sections, supporting build verification, in service assessment, and long term fleet maintenance planning.

Defence

Defence platforms operate under high load, impact risk, and demanding environmental conditions, where structural degradation directly affects mission readiness. Inspection access is often limited and time for disassembly or depot level inspection is constrained.

Field deployable guided wave inspections enable stiffness loss, impact damage, and joint integrity to be assessed directly on the platform. This supports production acceptance, in service assessment, and condition based decisions without reliance on complex teardown or specialised inspection infrastructure.

Join our talent network

Would you like to stay informed about relevant job opportunities and working at SINTEG Systems? Sign up for our Talent Network!

NEWS

News and Articles

-

SINTEG Systems finalist in the JEC World 2026 startup booster programme

.

SINTEG Systems has been selected as a finalist in the JEC World Startup Booster 2026, one of the world’s most competitive startup programmes in the composites industry. Out of approximately…

-

SINTEG Systems selected for NATO DIANA 2026 Challenge Programme

.

Delft, The Netherlands (10 December 2025) – SINTEG Systems is honoured to join the NATO Defence Innovation Accelerator for the North Atlantic 2026 Challenge Programme. We are part of a…

-

SINTEG Systems joins CompositesNL

.

In june, SINTEG Systems officially joined CompositesNL, the leading industry association for the Dutch composites sector. As part of our introduction to the community, we had the opportunity to present…